OVERVIEW

Birmingham Airport serves 143 direct scheduled and charter routes and offers an additional 279 possible connections worldwide. With half a million businesses in its catchment, it has the second largest demand for business travel, second only to Heathrow at 600 thousand. The majority of these businesses are high value manufacturing companies that currently export goods worth over £25 billion each year to long haul markets but without any direct air links. Each year 3 million business people from the airport’s catchment must therefore first travel to London’s Heathrow Airport for connecting flights.

The A45 is a main arterial route through the West Midlands serving the UK’s largest regional manufacturing hub and providing a road link between the cities of Birmingham and Coventry.

The airport plans to increase passenger traffic by 27 million and transport movements by 500 thousand with the ultimate goal of achieving “National Airport” status. Costing circa £65 million, the project’s primary objective is to enable a greater range of long-haul aircraft to use the airport and therefore serve significant global destinations directly including China, South America, Japan and the west coast of the USA. To achieve this, the airport is extending its runway from 2.6km to 3km, during the period Summer 2013 to Spring 2014, and, from Summer 2012 to Autumn 2013, building a new 2km horse shoe shaped diversion of the A45, making room for the longer runway.

Commissioned by VolkerFitzpatrick Colas JV, on behalf of its client Birmingham International Airport, SDS was tasked to supply and install surface water and sustainable drainage systems.

WHAT WE DID

SDS supplied and installed three bespoke GEOlight® attenuation tanks for the roadside scheme and one bespoke GEOlight® attenuation tank airside. Together, these have a combined capacity of 1700m3.

The tanks are used with separators in order to extract pollutants such as oil.

RESULTS

The new road routing and runway extension significantly increases the impact on both the quality and quantity of surface water runoff. The design, which incorporates the SDS tanks, assists in controlling the risk of flooding and contamination of watercourses to an acceptable level.

The potentially high loading, both airside and landside, demanded that the bespoke tanks are able to cope with the increase in volume of high-speed traffic on the dual carriageway and in the number and weight of aircraft movements at the airport.

Despite the very short time frame available and the extreme February weather, which required the project to be completed in deep snow, the tanks were installed quickly and within the restrictions of the main contractor’s programme.

3

1

1,700,000

SDS GEOlight®

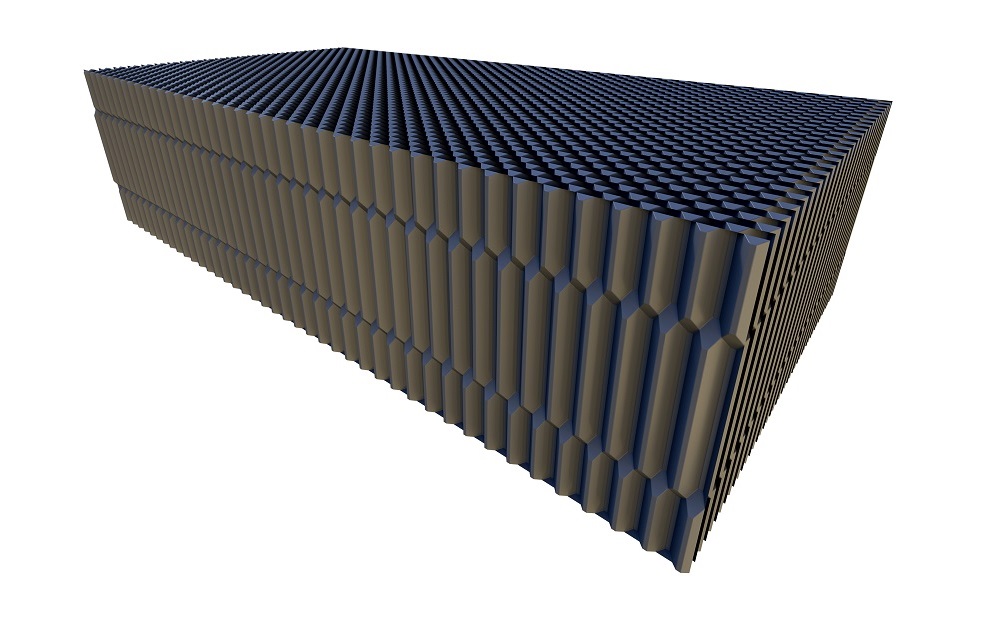

SDS GEOlight® is an ultra-lightweight honeycombed modular structure, the ready to install units are preformed to provide an underground stormwater storage facility, for the application of stromwater management.

SDS GEOlight® is an ideal material for cost efficient and maintainable underground water storage during storm conditions. It is constructed entirely from post-consumer recycled PVC waste, which is normally destined for landfill.

It can also be applied in many different ways, including water recycling, water pollution control and embankment protection.

Discover how the SDS portfolio can benefit your development and get in touch now.